Tunascan®

Tunascan®

3D Vision – Automatic tuna sorting system.

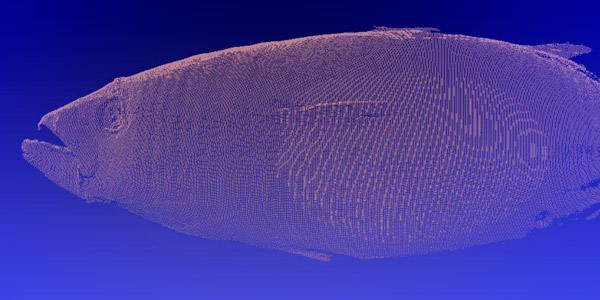

The technology used to analyse tuna is 3D laser profilometry, which converts each scanned piece into a cloud of reference points in space.

The global innovation is the ability of TUNASCAN® to process this 3D data into reliable results > 95% in species and > 98% in weight, or its ability to detect damaged fish.

Its high processing speed allows sorting up to 50 tonnes of tuna per hour. The biggest technological breakthrough is how TUNASCAN® thinks.

- Automatic tuna sorting system using artificial vision.

- Sorting capacity of up to 50 tonnes per hour for sizes between 1 and 50 kg.

- 95% efficiency in determining the species of tuna.

- 98% efficiency in determining tuna weight.

- Using 3D laser profilometry technology, each piece of tuna scanned is converted into a cloud of three-dimensional data, which, once analysed algorithmically, determines the classification of each piece.

- Guarantee of food safety and quality in the processed product by means of complete traceability control.

- Technological equipment that can be integrated into the company’s ERP, allowing real-time control of production and managing databases and statistics for rapid decision-making in the plant itself or remotely.

- TUNASCAN® allows the change from low quality manual work to state-of-the-art industrial equipment that is easy to use and versatile, thus enhancing the company’s social responsibility.

- Its resistance and durability has been tested for years in aggressive industrial environments, under extreme conditions of humidity and salinity.

- Maximum adaptability in the design and installation of the equipment to the requirements of each customer’s plant.

- Manufactured with high quality components and world-renowned technology.

No human error.

World’s first scanner to classify

tuna by size and species.

Autonomous Equipment.

Sorts species between 1 and 50 kg, with

a speed of up to 50 tonnes per hour.

Automatic Classification.

Each species of tuna separated

according to the customer’s needs.

In-line feeding system.

Tuna, regardless of their species mix, size or degree of damage, are unloaded into a hopper and correctly separated and aligned until they reach the 3D scanning area using different conveying elements.

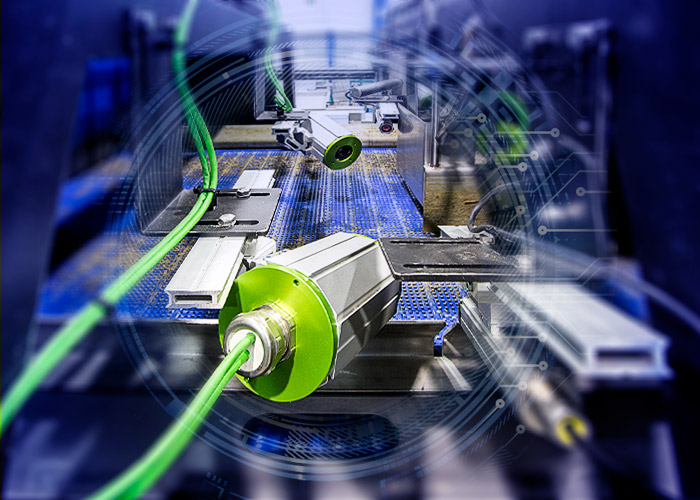

3D scanning.

Advanced TUNASCAN® technology, unique system that scans each piece of fish one by one, extracting the necessary information, via artificial intelligence algorithms and neural networks, to classify by species and size. This process is not affected by the usual presence of ice or frost.

Automatic sorting into specific containers.

The user can define the sorting criteria, assigning a specific type of piece to each container (species and size). The sorting line designed by Marexi allows the stowage without the need for human intervention.

+95%

Efficiency

determining the

species of

tuna.

+98%

Efficiency

determining the

weight of the

tuna.

50 t/h

Sorting

capacity

for sizes

up to 50kg.